4 Things you need to know about Machine Vision Technology

Have you ever used a scanner on your mobile phone? There is an option to take a picture and search it on the web. The camera will take a picture and show you similar results from the web. This is also the case with QR codes. You can easily find QR codes on a lot of products. All you have to do is to turn on your scanner app and scan the code. If you have not done any of these yet, here is another example.

You went to a department store and saw the cash counter, right? There is a scanner that scans the barcodes from products. In this way, the cashier won’t have to input everything by hand. Instead, they will put the barcode in front of the scanner and it will automatically get on the computer. Thus, you get your bill in no time.

All these examples show how machines use images, process them and use them as a reference. So whether you want the exact information of something or want to get it into the computer, it’s easy. We now have machine vision technology that does it all.

What is Machine Vision?

To say it simply, it is a technology that helps us get our work done through processing images. Softengi has further details about it like how you can choose the right company to get the best service. So you can go to Softengi and read more about it.

1- What does it do and how?

This technology helps you in automatic inspection, process control, and robotic guidance and even with the analysis of different applications. And it does it all through image processing.

Another important thing that you should know is that machine vision is not only an individual technology. It includes a combination of various other technologies. Therefore, different hardware and software products, expertise, actions, methods and integrated systems work together. As a result of all this combination, we get the technical capability to solve our real-world problems.

2 – Inspecting images and sorting them

As the process starts from image processing, you must know that there will be other processes too. The first step is to view an image and then its inspection starts. It will inspect the image and the process.

We will discuss the Pick and Place first.

There are robots in the workplace. So you are supposed to provide information to the robot. Make an image of the things it has to pick and where it is supposed to place them. This allows you to make your task easy. All you have to do is to make a colorful image and feed it into the robotic system.

The robot will detect the object from the provided image. Afterward, it will pick it up from the conveyer and take it to its destined location. Thus, the machine vision system allows you to design something and implement it on the system to make your job easier. This reduces human labor and increases working efficiency.

Industrial use

Various industries make use of this technology to regulate their work. The industrial sectors that use it include, automotive, food and beverages, electronics, intelligent transport system and traffic on the road. But this is not limited to them only.

TV broadcasting areas, scientific developments, pharmaceutical industries, printing, labeling and even packaging also use it. And in addition to all this, even a lot of medical imaging also involves a beneficial use of this technology.

3 – Equipment that you will need

The equipment that you need depends completely on your use. If you need to use it in a departmental store, the equipment will be different. Just like that, the equipment for the manufacturing plant of electronics will be completely different. Therefore, if a sector requires only limited equipment, the parts will be less.

For example, the system is responsible for inspecting a product when it comes in the process. And by inspection, it means that it will check details of the product. This also involves checking for any labels and their information. So it will have to go through everything about the product carefully. It must check everything that is in the system. So if the system tells it that there should be a label on the top right of the product, it will check it. In case of failure, the machine will diagnose it.

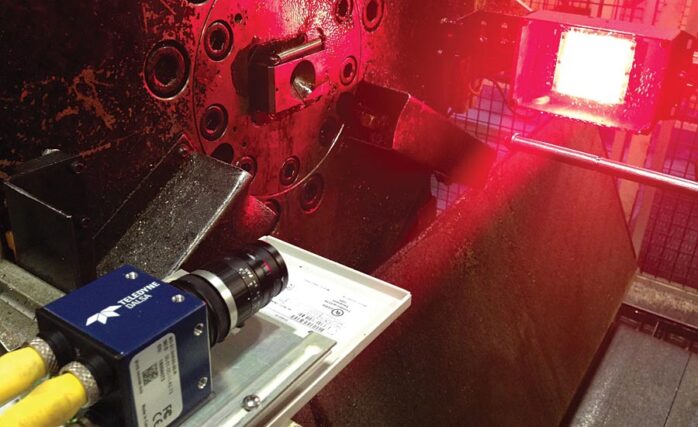

4 – The cameras

The most important thing in vision technology is the presence of cameras. This is the only thing that should always be there irrespective of the use. Although the size and features of the cameras may vary depending upon the nature of use, they must be present. Because they are the first line of action. A camera will go through the image and check for everything that it is supposed to.

Depending on the use, the features, interface, pixels and resolution of the cameras will differ.

For example, machines in the manufacturing industry will require better performance. Why? Because it has to go through the small details of the product from its entry to the finish line.

On the other hand, a scanner at the departmental store only has to scan the barcodes. Therefore, it does not require much technology and features. That is why only the pixels and resolution are important there. They will allow the camera to go through the barcode and scan it.

Thus, depending on the use, there are different cameras that are in use in machine vision. These include;

Smart cameras

If you require specific information from the image of an application, you will need a smart camera. It will generate descriptions and thus, make its decisions to provide you with details.

3D cameras

If you need to know the depth of products, you will need a 3D camera. It will process the image from different angles and give you the shape.

Thermal image cameras

It will check the heat areas of the image and give you the needed details.